Gum Ghatti

Gum Ghatti

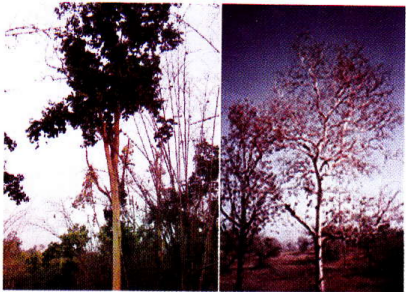

Gum ghatti is the dried exudates of Anogeissus latifolia, a tree found in India and Sri Lanka.

Local names

Hindi: Dhawda, dhawa; Marathi:Dhaura; Telugu:Tirumanu, Chirumanu; Gujarati:Dhavdo ; Tamil: Vellainaga

Plant Source : Anogeissus latifolia

Family : Combretaceae

Distribution : The tree grows extensively all over the country, more commonly in the dry deciduous forests in the Western Ghats and dry plateaus of Vindhyachal, Satpura and Western Ghats range of mountains, extending in Maharashtra, M.P. Chhattisgarh, Bihar and Orissa. It is a large erect deciduous tree that may grow up to a height of 25 meters, with a smooth light colored bark. Sometimes the bark has whitish grey depressions caused by exfoliation of bark.

In addition to its use as a source of gum ghatti, the tree is also widely used for timber and tannin is-extracted from its leaves.

Production in lndia : 1200 tons per annum (approx.)

Other producing country: Sri Lanka

Harvesting/Collection of Gum

Method of harvesting/tapping : The trees are not usually tapped for gum.  The gum oozes out naturally from the bark through injuries and wounds mostly in summers and is collected manually. In some places artificial incisions are made in the tree bark to increase the gum yield. These incisions are made carefully so as not to permanently injure or kill the tree.

The gum oozes out naturally from the bark through injuries and wounds mostly in summers and is collected manually. In some places artificial incisions are made in the tree bark to increase the gum yield. These incisions are made carefully so as not to permanently injure or kill the tree.

Period of harvesting/collection : Maximum quantity of the gum is collected during the summer months i.e. from March to mid of June. During this time, as the weather gets warmer,the yield increases. Normally the largest crop is picked in April.

Yield: A tree on an average yields around 1-2 kg of gum in a year. Gum yield depends upon the locality, size and vigour of the growth of tee and method of tapping.

Processing and Value Addition

Harvesting and grading of gum ghatti are done by methods similar to those used for gum karaya. The exudates are hand picked by the locals, mostly tribal and laid to dry in the sun for several days. At the processing centers,gum with bark and gum without bark are sorted. The barks are hand picked and removed from gum.The gums with bark are also fed to processing machine where barks are detached from the gum.The finer crushed particles are screened and removed. The gum is then hand-sorted into various grades according to color and amount of impurity.

Ghatti tears are further processed mainly by grinding in which the gum is pulverized to fine powder.  However, various other mesh separations arc also made as per the demands of the consumer. During the process of particle breakdown, impurities are removed from the gum by shifting, aspiration, and density table separation. Some work has been done on spray drying the soluble fraction to obtain powdered gum ghatti .

However, various other mesh separations arc also made as per the demands of the consumer. During the process of particle breakdown, impurities are removed from the gum by shifting, aspiration, and density table separation. Some work has been done on spray drying the soluble fraction to obtain powdered gum ghatti .

Storage and handling : Graded gum ghatti is usually packed in burlap bags of 50 kg capacity for storage and transportation purposes. Warehousing in a cool, dry place is recommended for extended storage. If the gum becomes damp, it tends to agglomerate and form lumps.

Quality control

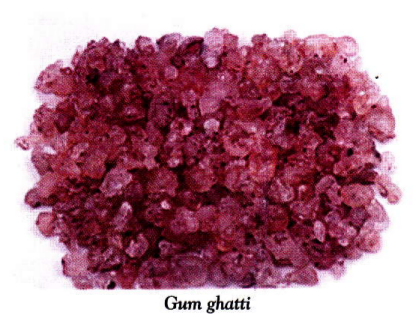

The main quality criteria at the sorting stage are colour and foreign matter, although even after grading the quality of consignments is often variable. The higher grades should be cleaner and paler than the lower ones, which may be dark brown in colour and have bits of bark present.

Typically, three grades of gum ghatti are available which are exported to various countries. These are No. 1, No. 2, and Unassorted grades. The No.l grade is light in color with low levels of ash and high viscosity.Number 2 grade is light amber to brown and the unassorted grade is dark brown to nearly black in colour. A BIS specification (IS 7239:1974) exists for food grade gum ghatti.

Properties

- The colour of the gum varies from whitish yellow to amber; though the presence of impurities sometimes imparts a brownish colour to the gum.

- Gum ghatti is partly soluble in water and forms a colourless mucilage.

- Gum ghatti is a moderately viscous gum lying intermediate between gum arabic and gum karaya. lt forms viscous solutions at concentrations of about 5% or higher and exhibits typical non-Newtonian behaviour.

- The emulsifying properties of gum ghatti are excellent and considered to be better than gum arabic and thus used in more difficult-to handle systems.

- Gum ghatti solutions are sensitive to alkali. Viscosity increases sharply with pH upto a maximum at about pH of 8.0 and above that the solutions tend to become above that the solutions tend to become stringy.

- Gum ghatti is approved for food use and is in the GRAS list under the Food, Drug and Cosmetic Act, U.S.A. It is non toxic and is not metabolized in human.

Industrial Applications

Gum ghatti is used

- As an emulsifier and stabilizer in beverages and butter containing table syrups.

- As a flavour fixative for specific applications.

- In the preparation of powdered, stable,oil+soluble vitamins.

- As a binder in long-fibered light weight papers.

- As an emulsifier of petroleum and non petroleum waxes to form liquid and wax paste emulsions.

- ln combination with polyacrylamide to aid in the polymerization and formation of uniform and discrete prills of cros-linked polystyrene.

- As drilling mud conditioner and the acidizing of oil wells.

- Used in powdered explosives to improve resistance to water damage.

చివరిసారిగా మార్పు చేయబడిన : 3/1/2020

This topic provides information about Guar gum.

This topic provides information about Gum arabic, ...

This topic provides information about Guggul or In...

This topic provides information about Asafoetida.